ENVIRONMENTAL TECHNOI OGY LEADS BRIGHT FUTURE,

GREEN TEXTILE MAKES COMFORTABLE LIFE!

About Us

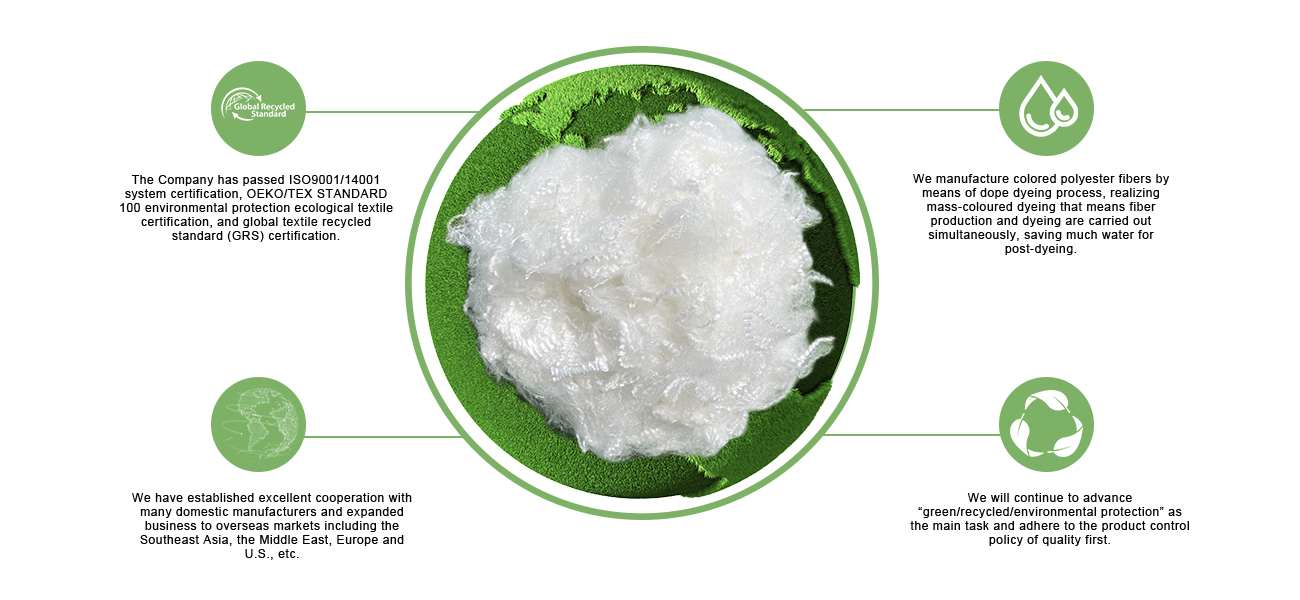

The company has been dedicated to the research and development, production, sales and services of environmentally friendly polyester fibers. Several domestic advanced production lines of polyester staple fiber and colored fiber as well as modified polyester staple fiber can meet various needs. Its main products, made in pursuit of the idea of “no dyeing and environmental protection, green textile”, include down-like fiber, recycled polyester staple fiber, superfine denier fiber, colored fiber, hollow fiber and functional fiber and other varieties. We produce recycled polyester staple fibers from recycling of polyester products, helping reduce waste and energy use. We manufacture colored polyester fibers by means of dope dyeing process, realizing mass-coloured dyeing that means fiber production and dyeing are carried out simultaneously, saving much water for post-dyeing. We have established excellent cooperation with many domestic manufacturers and expanded business to overseas markets including the Southeast Asia, the Middle East, Europe and U.S., etc.

Featured Press

Hollow vs Solid Polyester Staple Fiber: Which Should You Choose?

Textiles, home furnishings, automobile interiors, nonwovens, and industrial items all make extensive use of polyester staple fiber (PSF). The two main types—solid and hollow PSF—differ in internal structure, which affects weight, insulation, resilience, cost, and performance. Selecting between them depends on product needs, performance goals, and budget. Understanding the Structural Difference

Polyester Staple Fiber vs Nylon Fiber: Cost and Performance

Synthetic fibers dominate global textiles due to their consistent performance, durability, and cost efficiency across apparel, home, and industrial applications. Two of the most common are polyester staple fiber (PSF) and nylon, which differ in composition, properties, performance, and cost. This comparison examines their cost, mechanical performance, applications, environmental impact,

How to Choose the Right Recycled Polyester Staple Fiber Supplier: A Complete Guide

As sustainability becomes a core principle for textile brands, fashion houses, and industrial manufacturers, recycled polyester staple fiber (rPSF) has risen in importance. Recycled polyester staple fiber offers environmental advantages—reduced waste, lower energy usage compared to virgin polyester, and reduced greenhouse gas emissions. However, finding the best deal is not the

How Fiber Length and Denier Affect Recycled Polyester Staple Fiber Performance

In sustainable textiles, recycled polyester staple fiber (rPSF) has emerged as a key component. Whether used for yarn, non-wovens, automotive textiles, home furnishings, or technical industrial applications, performance depends heavily on two primary physical attributes: fiber length and denier. Understanding how these characteristics influence final product behavior is essential for material developers,

Polyester Staple Fiber in Automotive Soundproofing: A Complete Guide

Automotive noise, vibration, and harshness (NVH) remain key challenges in vehicle design. To meet growing demand for quieter, more comfortable rides, manufacturers increasingly use Polyester Staple Fiber (PSF) for lightweight, cost-effective sound insulation, absorption, and vibration damping. This article examines PSF’s role, properties, applications, and future trends in automotive soundproofing.

Polyester Staple Fiber in Sofa and Upholstery Fabrics: A Complete Guide

Polyester staple fiber (PSF) has emerged as one of the most widely used and versatile materials in the furniture and upholstery industry, particularly for sofas, chairs, and other soft furnishings. In a market where durability, comfort, cost-effectiveness, and aesthetics all play vital roles, polyester staple fiber stands out as a